Vapor Blast Systems for Automotive Remanufacturing and Restoration

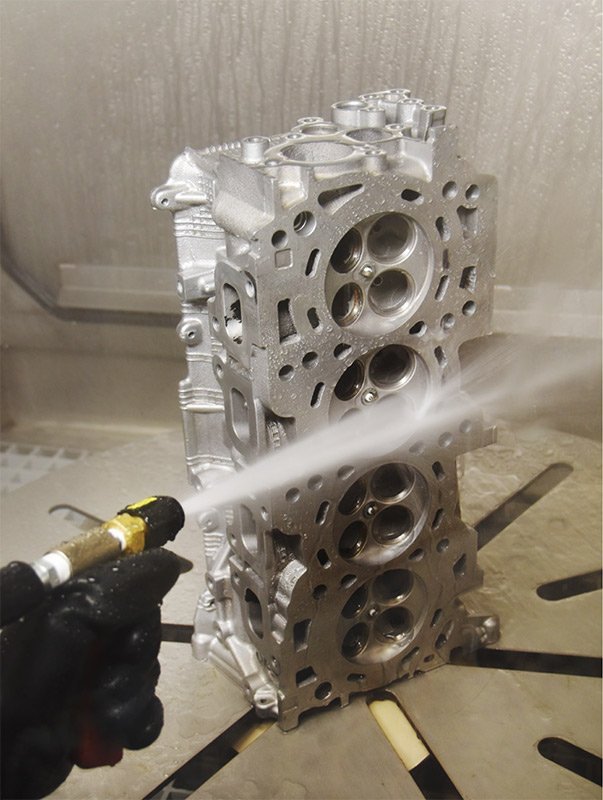

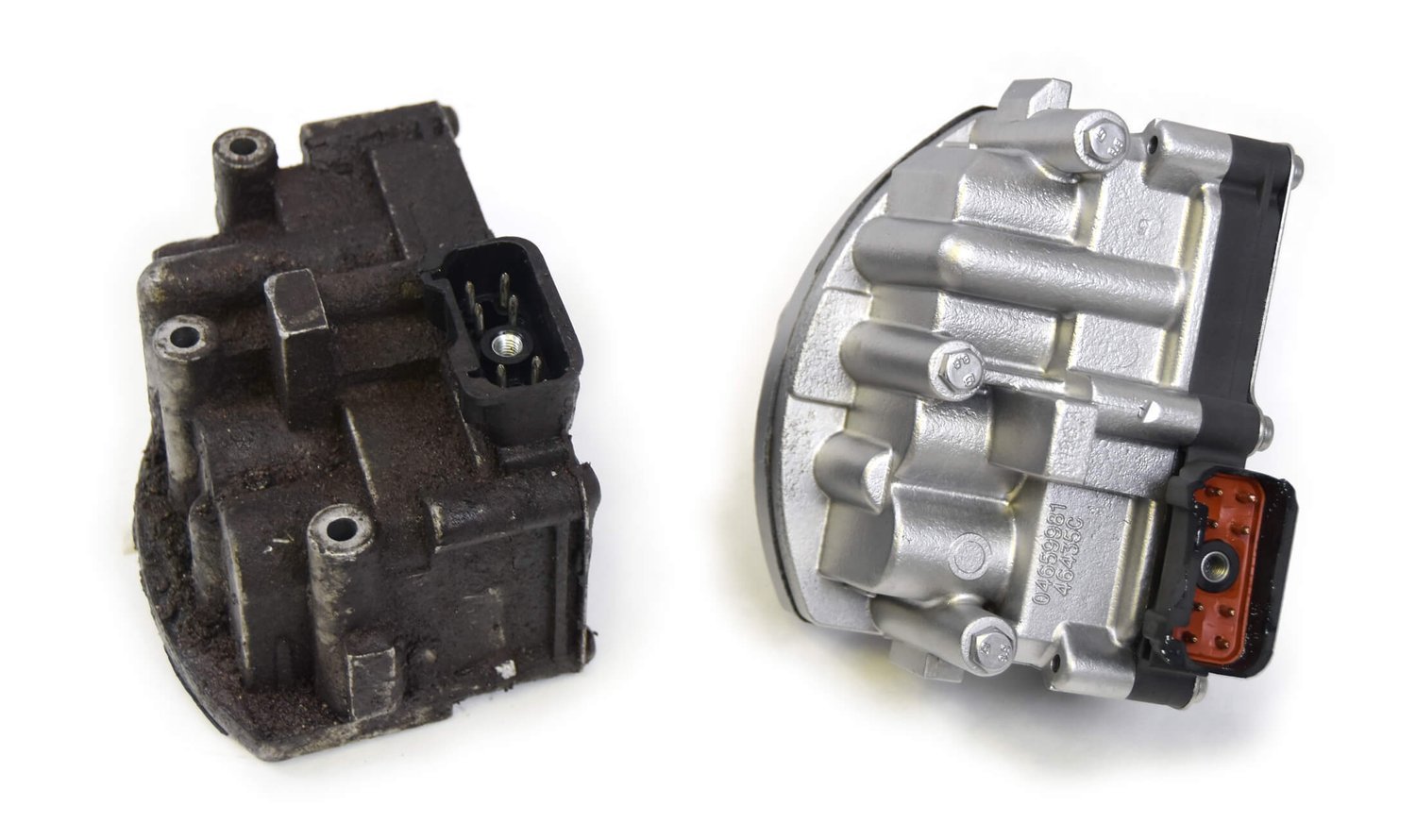

Wet Technologies has developed efficient wet blasting systems, also known as vapor blasting systems, for the automotive remanufacturing and restoration industries that are able to restore small and large automotive parts to like-new.

These low-maintenance, customized solutions compress production cycles and result in higher margins. We have manual and automated vapor blasting cabinets that can be built for any application.

Our process uses less abrasive media than dry blasting (little or no chemistry), eliminates several steps, and reduces time and floor space.

Prior to vapor blasting, parts that had contaminants such as rust, oxidation, paint, grime, oils, and burnt scale were generally pre-washed, soaked, shot blasted and / or dry blasted, and then washed and dried again. All before they could be rebuilt.

Consult with one of our experts today and see how a Wet Technologies’ vapor blasting system can enhance your REMAN lab and restoration process.

What our customers say about us

“It can take a part that’s 40-50 years old and make it look brand new.”

— Haydon Brother’s Automotive | Anaheim, CA | Manual WT50SS Installed 2015, still in use today

Blasting Process

Which vapor blasting process is right for me?

We provide solutions based on your application and finishing needs. All of our systems are offered independently closed loop, as well as open loop, and can also be designed to feed and draw from a customer’s plant waste water treatment process.

A significant factor in our reputation is our ability to run the highest concentrations of certain medias in the industry.

Our slurry delivery system provides the most even finishes with faster process times, and lower media consumption rates.

Combination Systems Available: We can combine high pressure water and wet blast slurry processing into the same system.