High Pressure Water Blast Systems: No Slurry Required.

A Range of Processing Options from Manual to Fully Automatic.

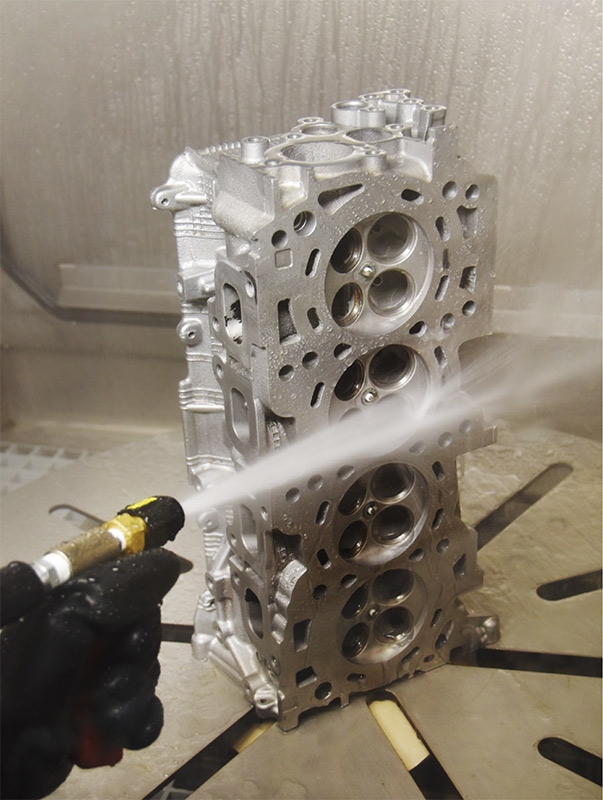

diesel reman wet blast cabinet

While we’re well known for our wet blast slurry systems, we offer a wide range of high pressure water blast systems for applications where slurry is not required. All of our systems are offered independently closed loop, as well as open loop, and can also be designed to feed and draw from a customer’s plant waste water treatment process.

Manual: We offer a base 1,000 PSI, closed loop system for lighter duty applications, or more aggressive 1,500 to 3,000 PSI adjustable range cold or heated systems.

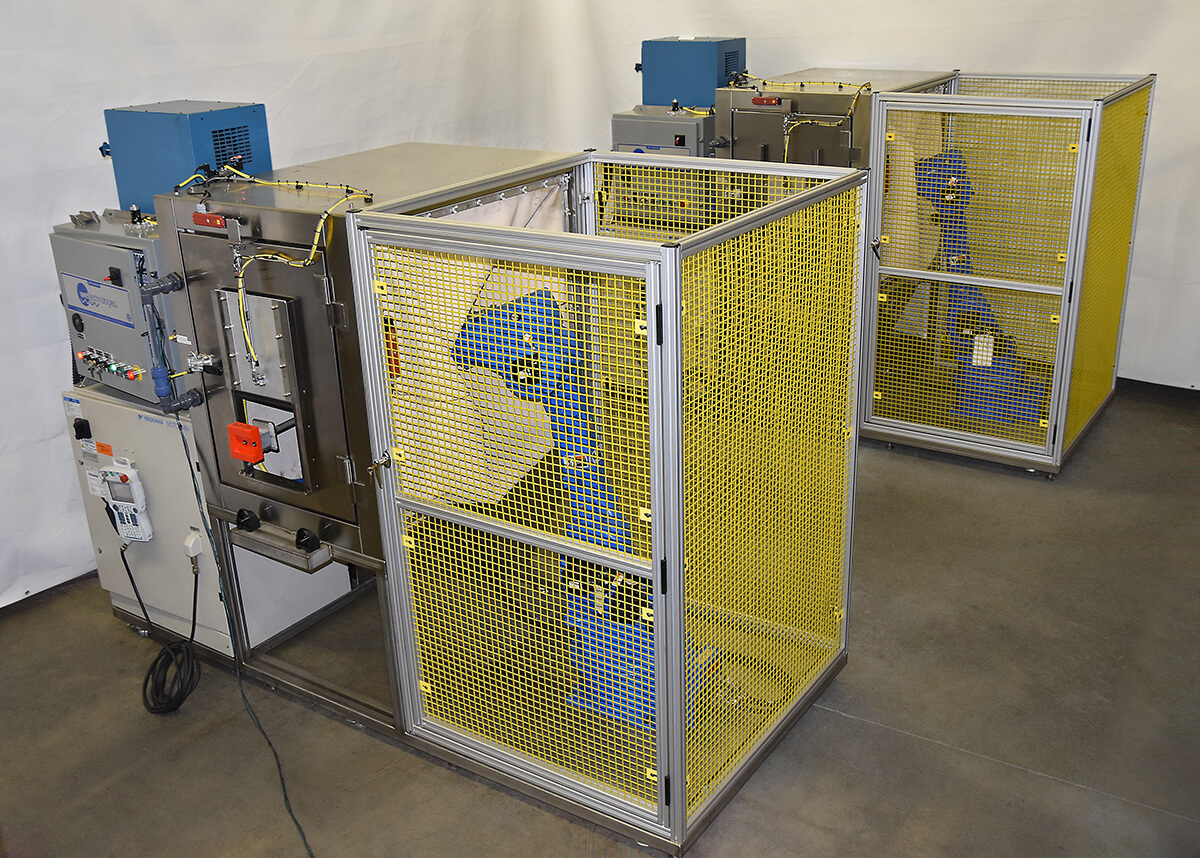

Automation: Batch Loaded, Rotary Indexing, and Robotic Systems. Pressure range from 1,000 to 7,900 psi.

Configurations: Standard cabinet sizes include 36”, 50”, 60”, and 72” square. We can readily supply custom sized cabinets for special applications, all the way to large platforms and walk in rooms.

Combination Systems: We can combine high pressure water and wet blast slurry processing into the same system.

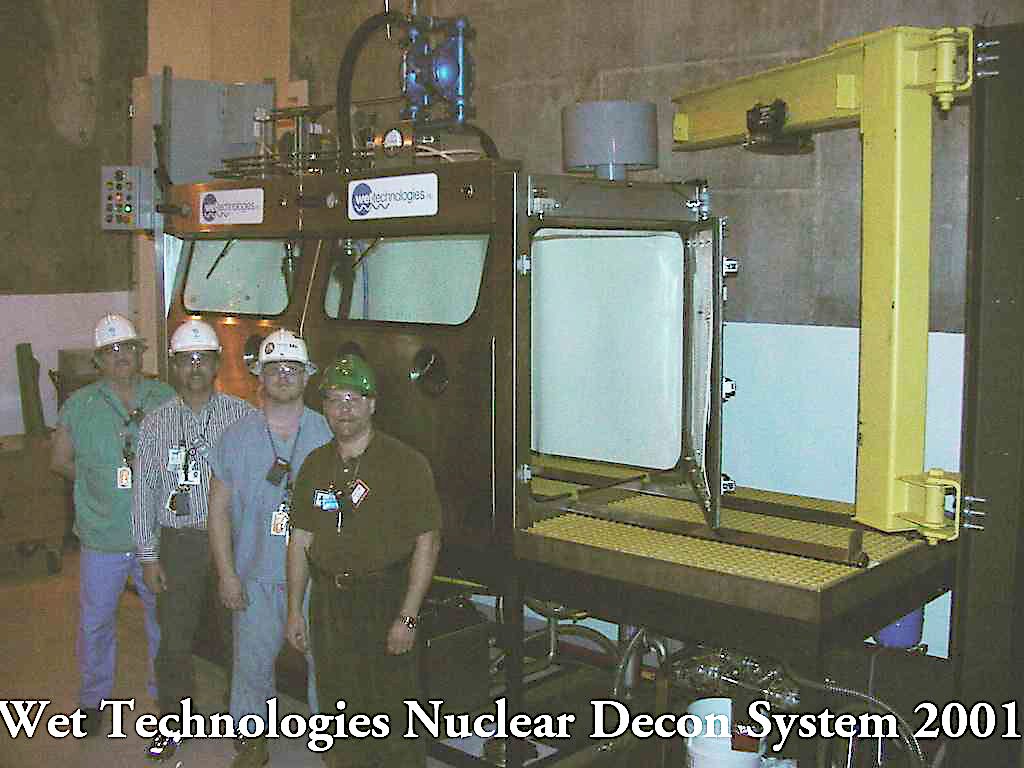

Who Relies on Solutions from Wet Technologies?

Tinker Air Force Base, BorgWarner, Caterpillar, Cummins, Texas Utilities, TransCanada, Edwards, Ebara, Deutz, Framatome, Parker Hannifin; to name a few.

Advantages of Wet Tech High Pressure Systems.

- Minimize or eliminate the use of chemicals and their disposal

- Save time by combining deoiling and descaling

- We offer the option to separate and remove both floating and emulsified oils

- Deep cleaning without imbedded abrasive

High Pressure Water Blast Systems from 1,000 to 7,900 psi

- Stainless steel, tig welded construction

- 230/460 Volt

- Adjustable pressure regulator

- Inlet pressure protection

- Heated water

- Low water level protection

- Oil separation and removal

As with all of our high pressure systems, additional safety factors are part of the design review.

Note: Closed loop filtration for our high pressure water blast systems is designed to provide separation of particles down to 5 microns in very low concentrations of under 1%. This option is not designed to handle higher concentrations such as those encountered on parts coming directly from machining centers with abrasive fines present such as “swarf”.

Additional options and custom/automated systems are available.

Back to Reman intro. | Back to Aviation intro.