Wet Technologies Applications

A Variety of Surface Finishing Processes

Wet Technologies engineers systems for a wide variety of finishing processes. In Aviation MRO and Automotive Reman, wet blasting supersedes dry blasting for clean, safe and precise removal of paint, grease, rust and scale. In coin minting and finishing of precious metals, our closed loop wet blast systems reduce or eliminate the loss of valuable material. In firearms manufacturing, beautiful finishes are consistently achieved, even throughout interior passages. For medical implants and instruments, biologically friendly surfaces are attained with extreme precision and little or no embedded material.

New Materials and New Markets

We’re discovering effective ways to apply our sustainable, safe and precise methods to new materials and markets, including Additive Manufacturing, and new alloys being created today. Use the examples below as a springboard to innovation in any surface preparation process. We can reduce or eliminate harsh chemicals and dust hazards. We can expect sustainable, repeatable results, and reduce process steps for better productivity and a healthier environment.

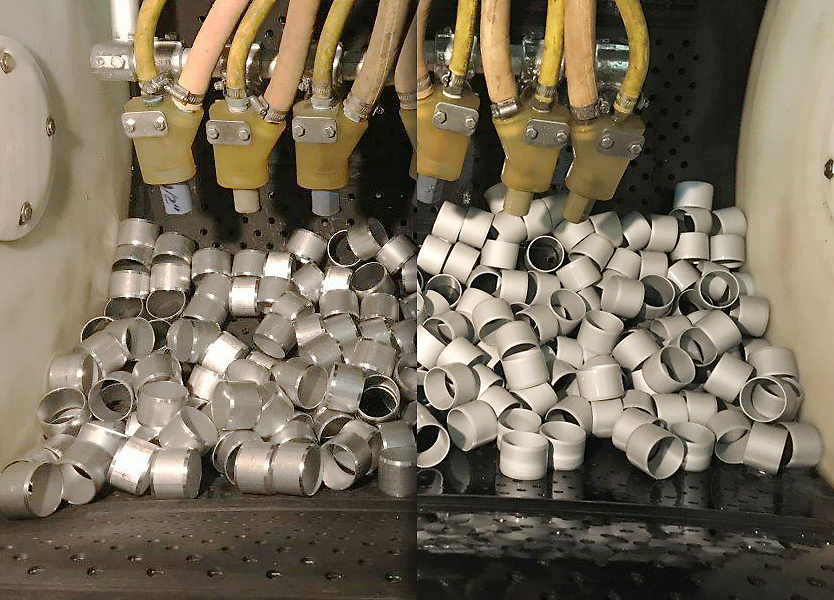

Deburring for Automotive

Stamping of transmission splines leaves fine burrs that are removed in seconds with no media imbedded in the surface. At the same time, wet blasting prepares the inside for a pressed bearing. Deep, sharp stress risers left by broaching are removed with fine slurry blasting. The result is a very large increase in lifecycle from the effects of fatigue.

Deburring for Precision Machining

Wet blasting removes fine burrs in machined titanium with no dimensional damage, while leaving a clean, uniform, matte finish.

Deburring and Cosmetic Finishing

Examples of deburring machined aluminum components: computer heat sinks, engine fuel rails, etc.

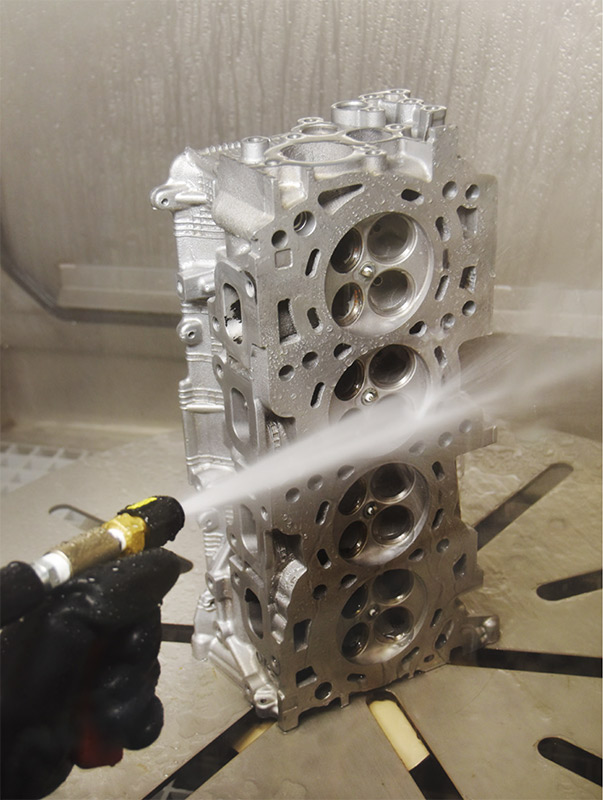

High Pressure Water Cleaning and/or Deburring

High Pressure Water-Only (up to 5,000 psi standard) is available for applications where media can not be used. Higher pressures available upon request.

Crack Detection for Aviation

Cracks are exposed with no media imbedded in the surface, leaving an even finish ready for liquid penetrate inspection or LPI. IMPORTANT: Dry blasting tends to mask/hide surface cracks.

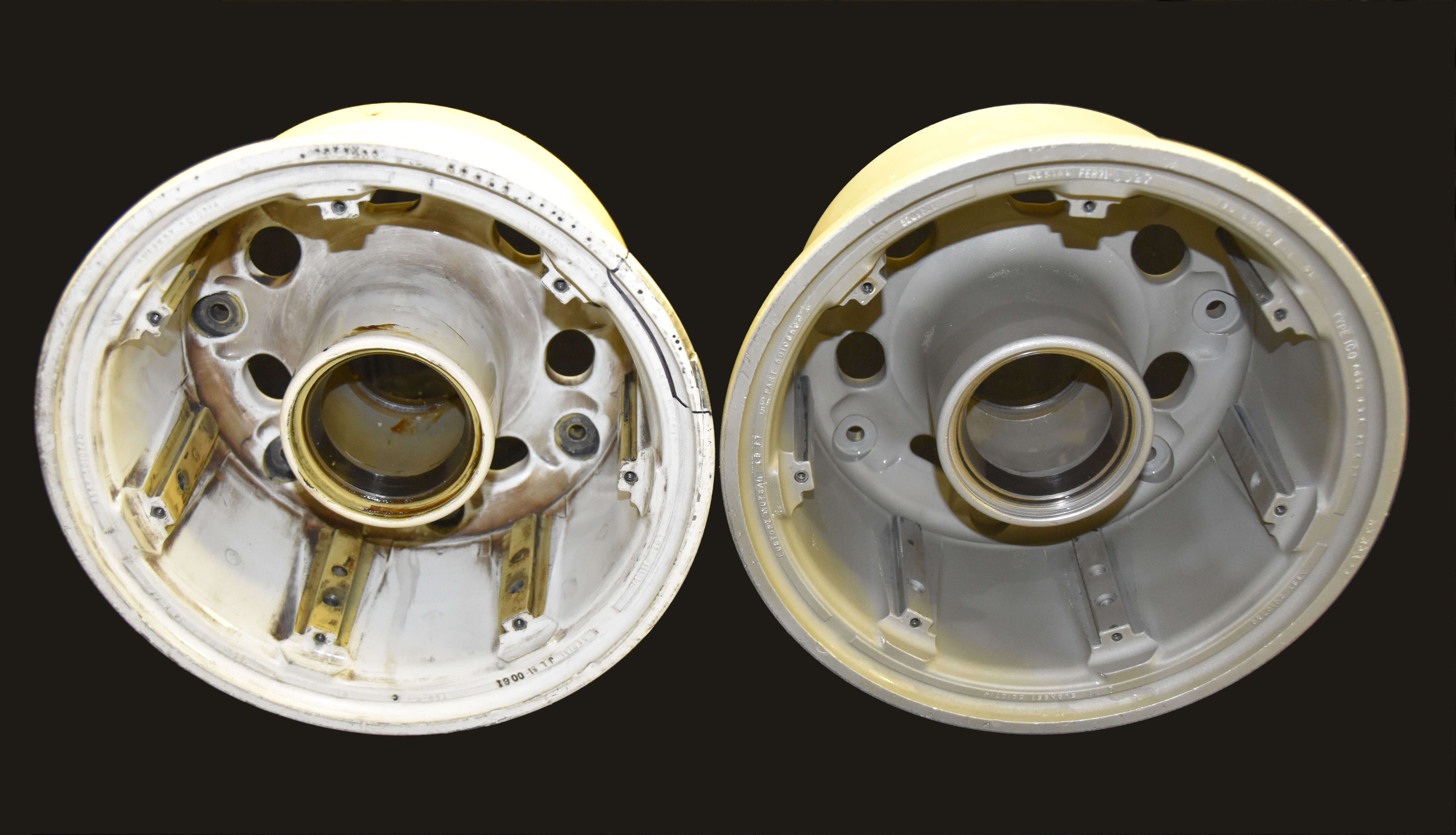

Automotive Rebuilding – Torque Converters

Wet blasting simultaneously cleans and provides a uniform surface finish.

Light oils and corrosion are addressed dust-free.

Automotive Rebuilding – Transmissions and General Parts

Wet abrasive slurry blasting offers deep cleaning of aluminum cases and can eliminate painting, while leaving a superior cosmetic surface.

Diesel Engine Rebuilding

Wet blasting combines several steps to clean oils and greases as well as removing corrosion and burnt-on carbon.

Circuit Board Cleaning

Plastic slurry blasting cleans while producing no heat or static.

Investment Casting Removal

High-pressure water systems are used to remove investment cast shell, and slurry blasting will perform the final clean.

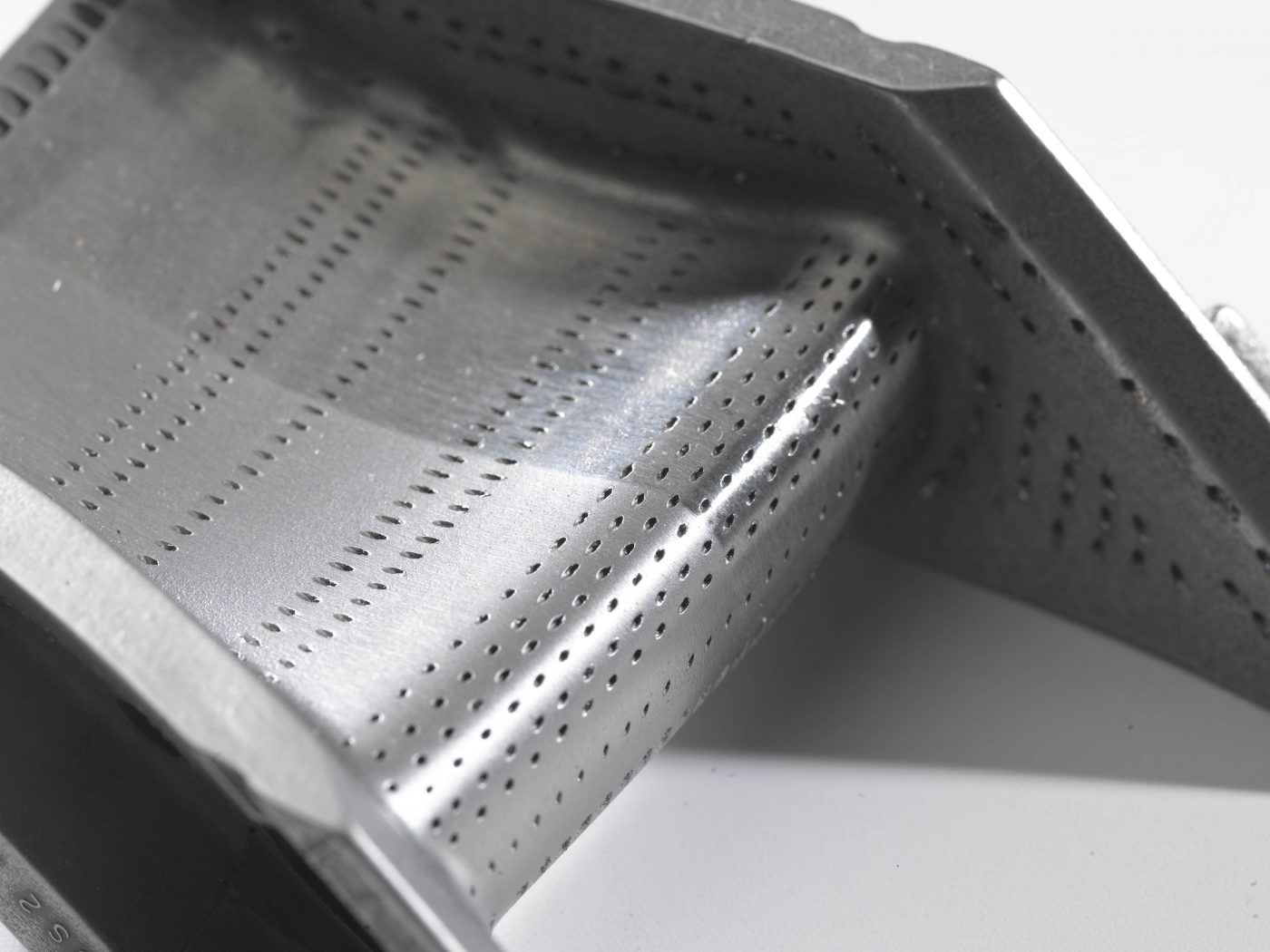

Semiconductor Tooling Coating Removal

Chemicals are eliminated, and process time is lowered; wet slurry performs delicate cleaning and removing of layers, all without damaging, warping or imbedding media. Parts include metal shields and ceramic tooling.

Plastic De-flashing

Using plastic in the wet blasting slurry removes flash with no damage to the substrate or static; parts are de-flashed, rinsed and dried in one system to meet a particulate-free “Millipore” cleanliness standard.

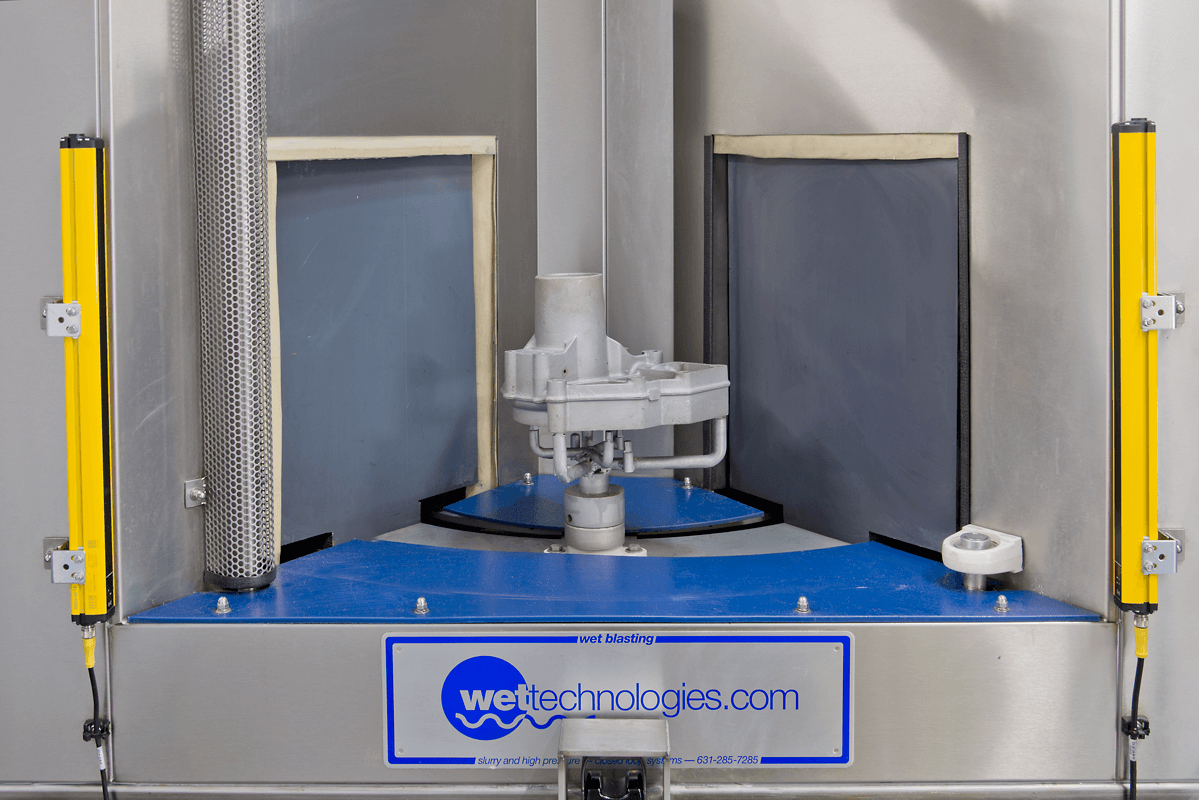

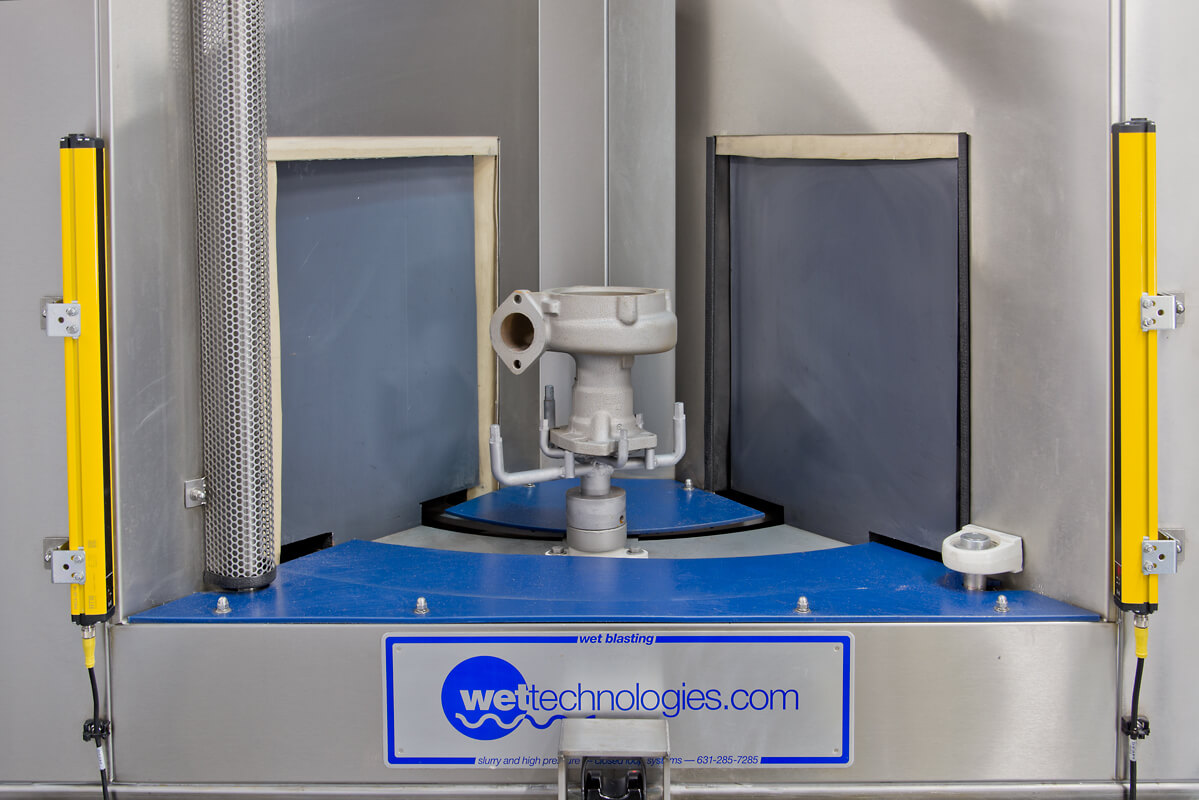

Marine Engine Overhaul

Parts are washed and deep-cleaned in one wet blasting step.

Mold Cleaning

Wet blasting enables simultaneous cleaning and polishing with no damage; edges are kept sharp and mold life is extended.

Aviation Wet Peening

Turbine blades, vanes and components are wet peened on the “N” and “A” scale using glass or ceramic beads.

Medical Implants and Instruments

Pre-plate uniform surface finishing and etching are achieved with no dust or imbedded media.

Cosmetic Blending

Machined aluminum is wet slurry blasted to blend in extrusion lines and to achieve a uniform dust-free finish.

Composite Bonding Preparation

Wet blasting etches the surface to create a light anchoring pattern, while leaving no media imbedded in the surface. This will increase bonding strength and eliminate post-cleaning.

Descaling

Wet blasting using various slurry, from fine to coarse grain, deep-cleans scale for cosmetics and prepares surfaces for painting in a dust-free environment, while importantly eliminating the need for caustic chemicals.

Paint Stripping

Wet blasting can strip paint in a dust-free environment and again, importantly eliminate health hazards from toxic coatings.

Silicon Wafer Stripping/Etching

Wet blasting can strip and etch silicon wafers dust-free and reduce part breakage by up to 40%.