Setting New Standards in Wet Blast System Performance

The following array of standard systems and manual configurations of wet blasting cabinets are available today from Wet Technologies. These models reliably serve the diverse needs of various industries across the country and around the globe. They are easily integrated into your work environment, and because they are closed-loop slurry blast systems, there’s no risk of dust explosions and no dangerous chemicals to handle. Cabinets may be made of stainless steel or molded plastic. Each system can be delivered and operate as is. Or, we will customize a machine to meet your specific operation’s production and installation needs.

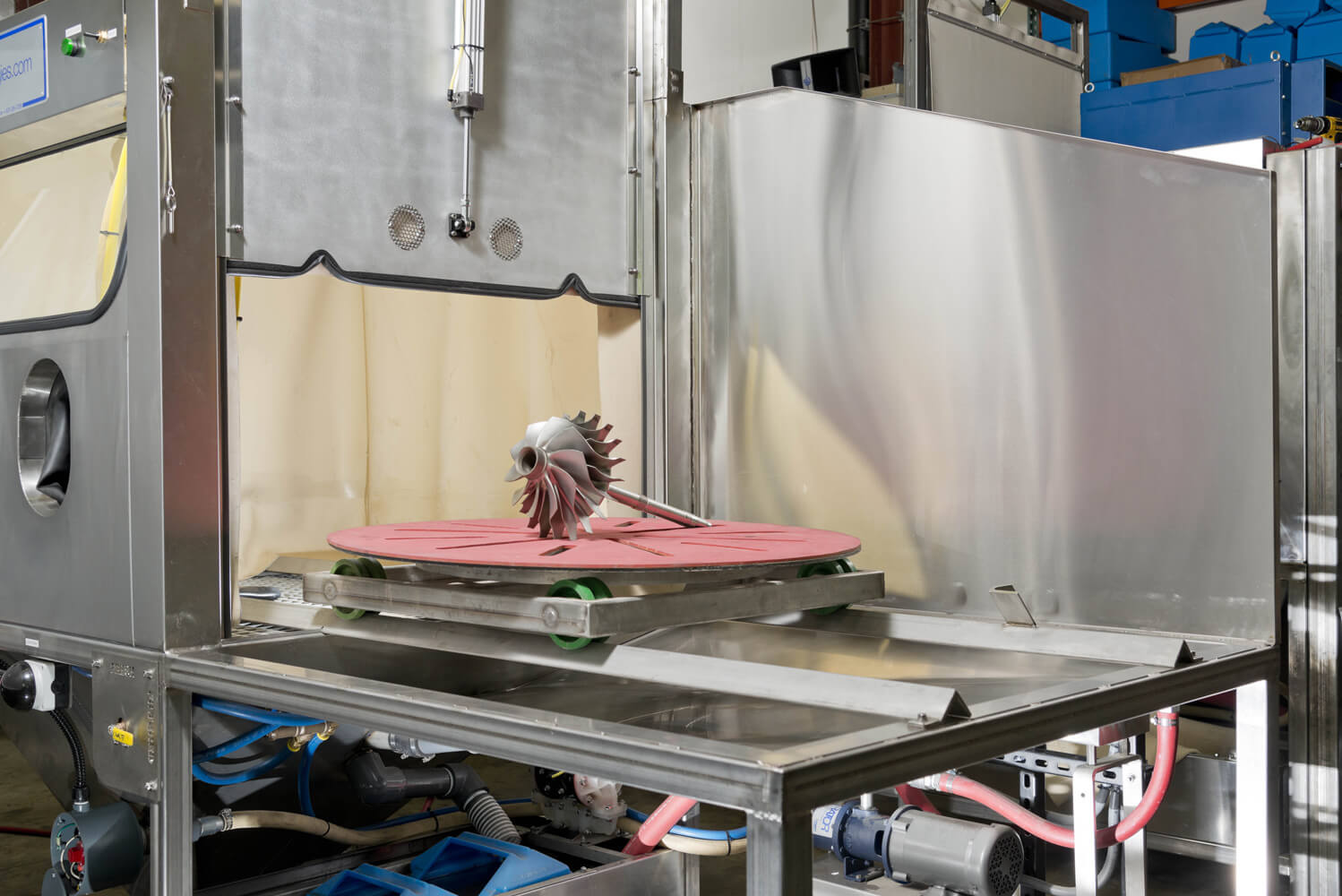

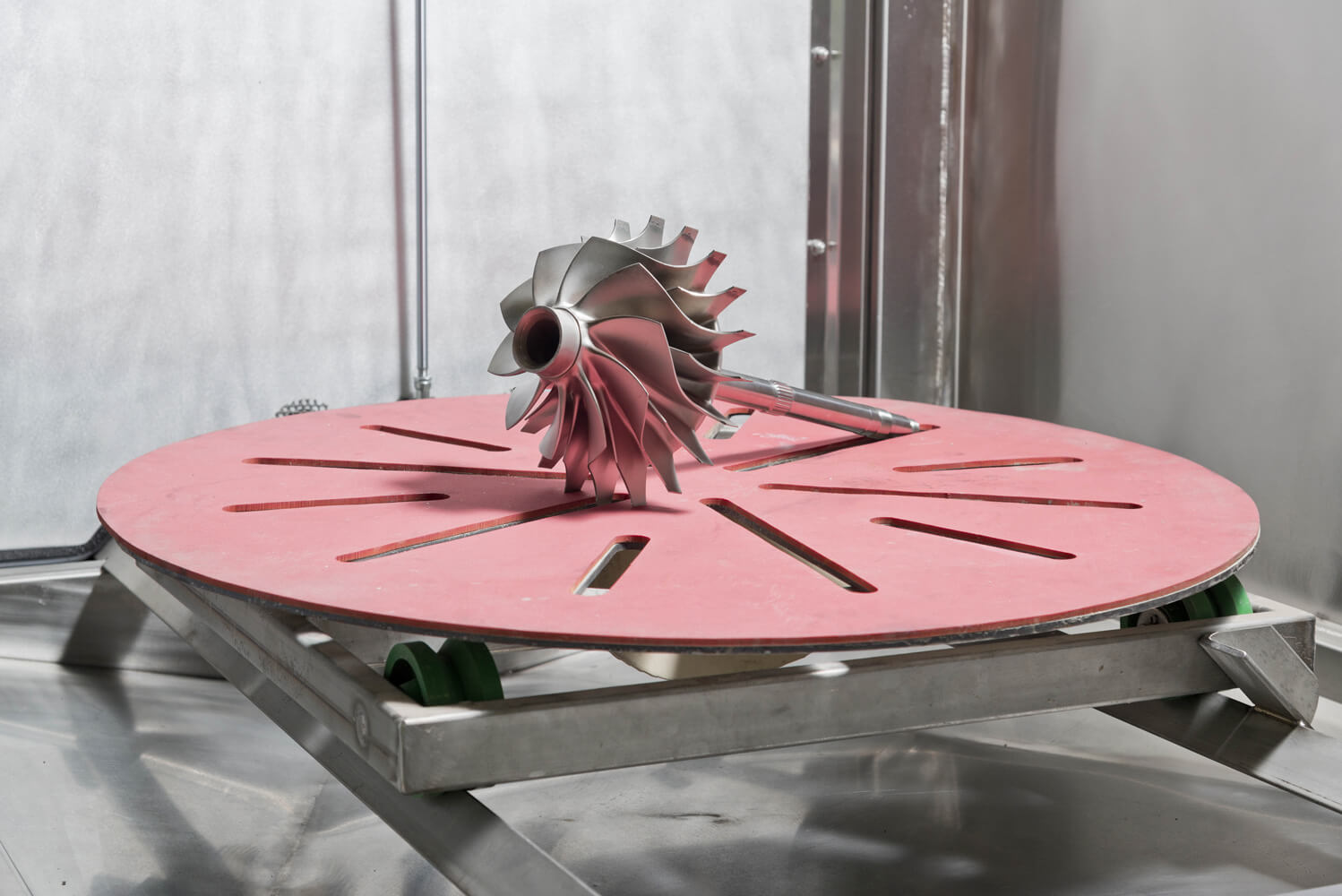

This demonstration of the Wet Technologies Stainless Steel 36” Wet Blast Cabinet shows our “standard workhorse” in action. High concentration slurry is visible through our unique monitoring device. Slurry is immediately homogeneous. The viewer window is rinsed on demand for continuous visibility and uninterrupted workflow. High pressure blast smooths the surface effectively without damaging details like a raised serial number. An efficient, precise, closed loop, clean and sustainable system.

Our WT50SS wet blast cabinet works great! All my floor operators are impressed by how quiet yet powerful it is. It’s definitely the best manual wet blast we have on our floor. Setup was easy and running it was intuitive, with very little time involved in getting it up and ready for production.