As the world’s technology continues to advance and evolve, the manufacturing industry has seen significant improvements. By partnering human expertise with machine learning and labor, manufacturers have made processes faster and less costly than in the past. In addition to that, manufacturing has also become more accurate and easily repeatable.

Today, manufacturers can modernize, simplify, and protect the integrity of their processes using data acquisition.

What is Data Acquisition?

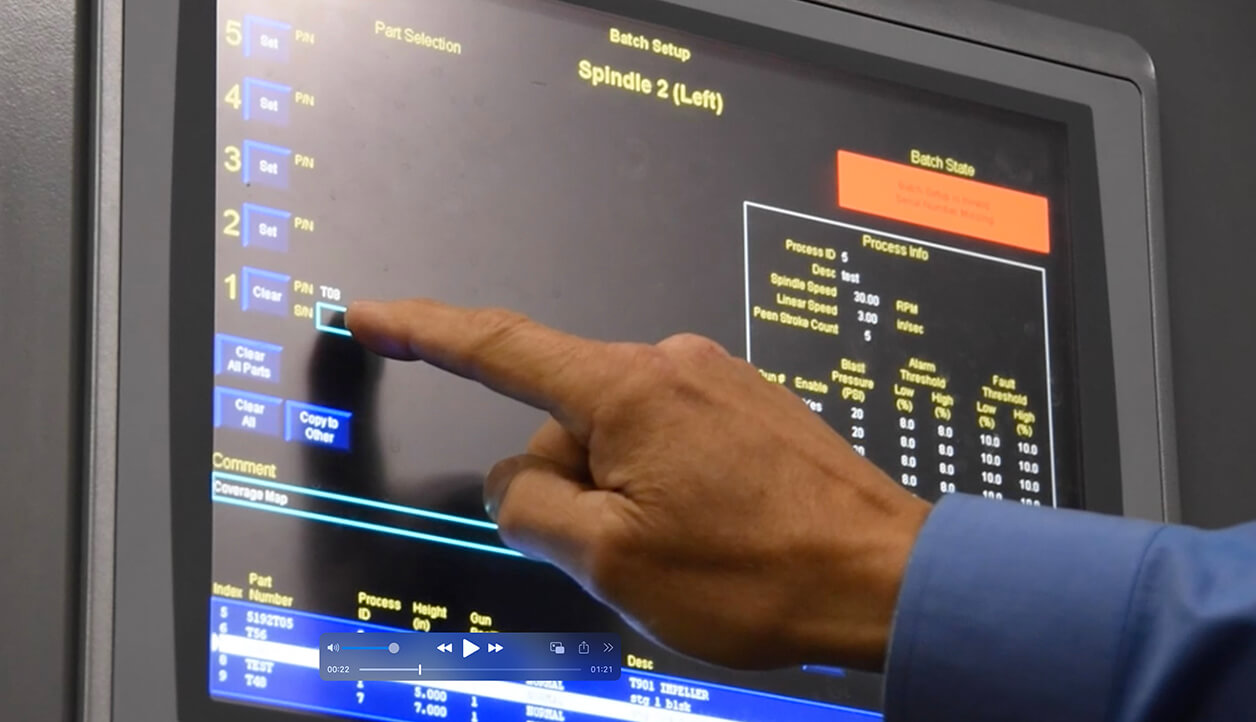

Data acquisition, also called DAQ, compiles real-time data during processes and analyzes it to help identify gaps and opportunities for optimization. A data acquisition system can include a variety of features – including sensors, monitors, and measurement devices – and then stores that data in the system’s computer. Depending on the use case, each DAQ system may be set up a little differently from one another.

For example, a piece of industrial equipment needs to perform the same process over and over again. In most cases, precision is essential. Data acquisition systems allow users to test the equipment for accuracy and consistency – and if any issues arise or if any manufacturing requirements aren’t met, the system can detect it automatically.

How Does Data Acquisition Affect Quality Control?

There’s bound to be some level of human error whenever an inspection is performed manually, but DAQ systems help take that possibility out of the equation. By monitoring processes in real-time, operators can test systems and verify that machines are performing and manufacturing parts correctly. And all the data collected by the system is objective and automated, eliminating the possibility of human bias.

With the help of DAQ, operators can identify issues immediately or sometimes prevent them before they happen. Data acquisition systems confirm that the equipment is functioning properly prior to beginning production, ensuring all standards and specifications are met. By improving this level of accuracy and repeatability, DAQ saves both time and money.

Finally, remote access to the data collected by your DAQ system allows you to continuously monitor systems, closely supervising processes as they happen. Tools like barcoding and laser etching even make data capture specific to the individual part, giving you oversight of and insights for every piece and stage of your operations.

DAQ also tracks compliance in manufacturing standards. With pre-configured processes and all data logged, manufacturers can see exactly how parts were handled and prove that all compliance standards were met. This traceability also holds everyone accountable for meeting the highest possible standards in their manufacturing, promoting safety and high-quality work.

Mailing List

Data Acquisition for Critical Parts in the Aerospace Industry

Aerospace is one of many industries that have benefited from data acquisition. Aerospace and aviation in general are very data-driven businesses – data is collected on everything they do and relayed to ground crews. But another thing to consider is that aerospace requires very precise manufacturing for all of its equipment in order to guarantee each piece fits perfectly together and operates properly. Identification and records for critical parts are meticulously maintained so that manufacturers can document the history of individual parts or batches of parts. Data acquisition provides traceability, ensuring that these parts meet compliance standards and are manufactured accurately and consistently over and over again. This makes processes more efficient and allows manufacturers to prove safety and reliability.

Data Acquisition in the Medical Field

The need for remote data acquisition continues to increase as more processes become digital, but the medical field still requires very precise machinery and supplies, making accuracy and accountability essential. Medical devices and medical implants save lives, but only if they’re high-quality and well-manufactured. With data acquisition, manufacturers can analyze and test parts against compliance standards before they make their way to doctors or patients.

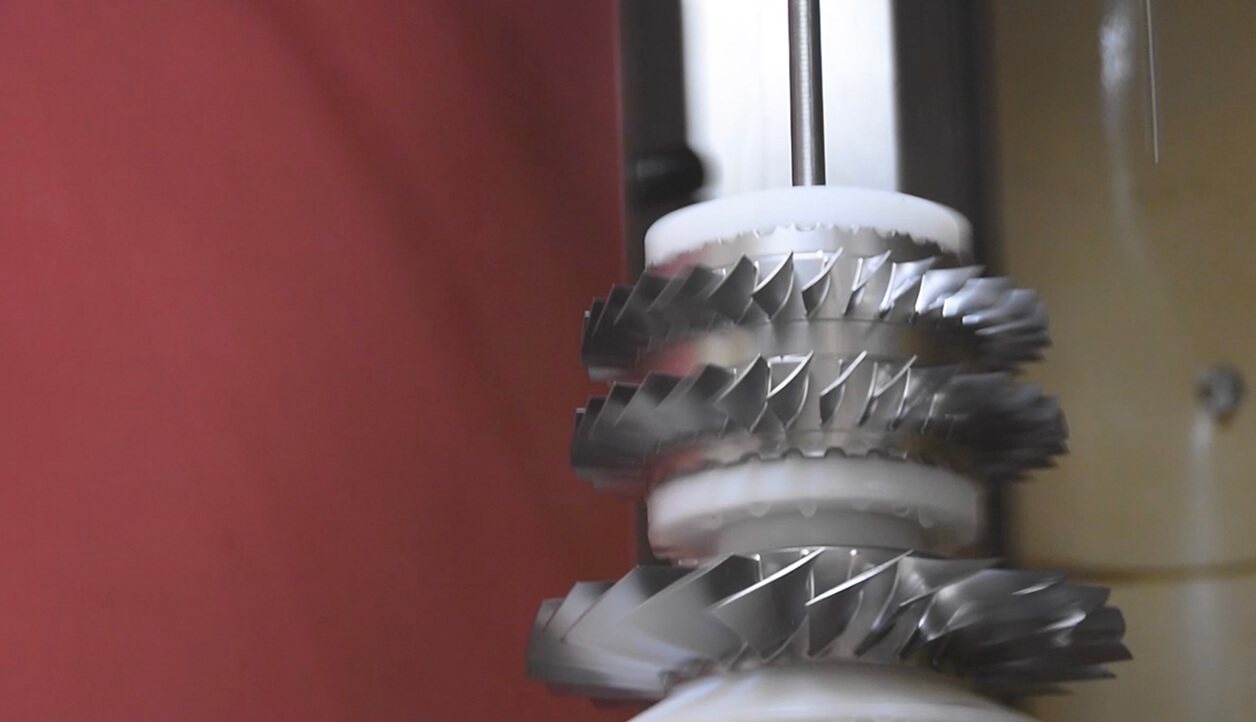

Modernize Your Wet Blasting with DAQ Technology

There are many ways to make data acquisition work for your business, and Wet Technologies is continuously adding these evolving technologies to our equipment.

By integrating data acquisition systems with your current operations, you could see both immediate and long-term improvements to your manufacturing process. Allowing computers to monitor, compile, and analyze real-time data also frees up your human employees to consider the big picture of your operations or even tackle other projects. And with so much data at your fingertips, you may discover new opportunities to strengthen and grow your business even further.

When critical parts are being manufactured or serviced, trust Wet Technologies to comprehensively understand your need to maintain integrity of the audit trail, and protect the full serialization of all parts and batches.

If you’re wondering how to integrate automated and intelligent data acquisition systems in your current surface prep and finishing operations to start saving time and money, contact us today.