Driving Automotive Reman Efficiency By Combining Process Steps

Compress Your Production Cycle for Higher Margins.

For the Automotive Reman industry, Wet Technologies has developed efficient wet blasting systems that compress the production cycle and result in higher margins. These systems condense common individual applications and eliminate several steps, reducing time and floor space.

In addition, the Wet Tech process uses less abrasive media than dry blasting, little or no chemistry, and reduces and contains waste.

Beautiful machine, very well built. I am extremely impressed with descaling and cleaning…I’ve blasted for years and it far exceeds most.

The machine is beyond what we expected. Training was informative and detailed. The pump is very easy to maintain. Working with Wet Tech and learning about the machines was a great experience.”

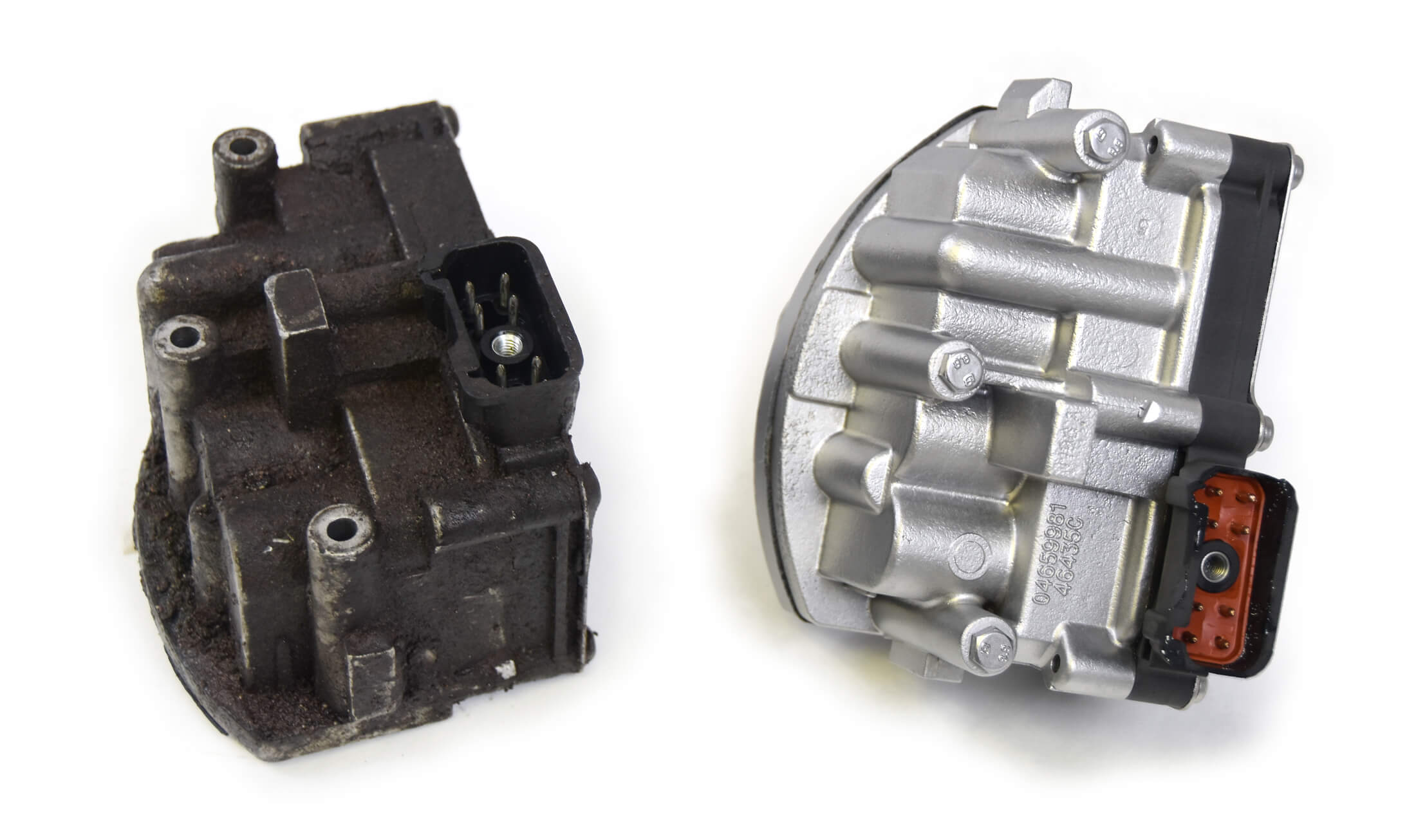

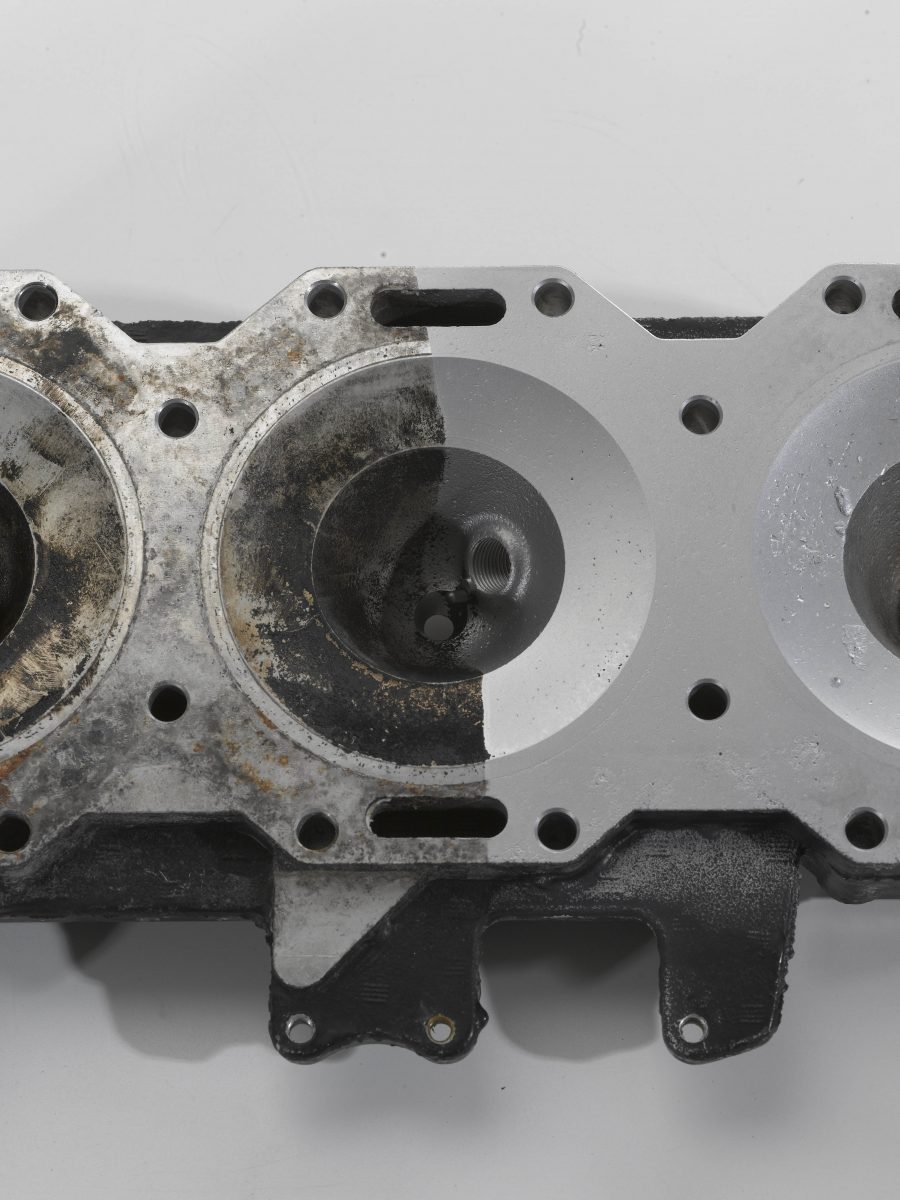

The rebuilding / reconditioning of engine, drive train, wheel, and brake components to as-new operating condition, prior to wet blasting, used to be a long multi-step process. Parts that had contaminants such as rust, oxidation, paint, grime, oils, and burnt scale were generally pre-washed, soaked, shot blasted and / or dry blasted, and then washed and dried again. All before they could be rebuilt.

The Wet Technologies automated system gives you an edge that saves both time and money. An example is the descaling system created for top NHRA drag racers.

High Pressure Systems: No Slurry Required

We offer a wide range of high pressure water blast systems for applications where slurry is not required.

Automate Diesel Engine Remanufacturing

Reduce the time it takes to reman components by roughly 1/3 to 1/2.

Engineered for Performance and Safety

Condense and compress the production cycles of common individual applications.