Nearly every machining process leaves some sort of burr that must be removed. But few agree on the definition of a burr, let alone a standard for describing them. “A burr to one engineer is simply a sharp edge to another.”¹

The Problem With Burrs.

Burrs can cause issues in downstream machining processes by preventing proper location of the part in a fixture, or interfering with a metrology device. Burrs that are not detectable visually or by feel may be easy to overlook. “This is often the case with close-tolerance holes. When a burr is left on the edge of a hole, plugs and thread gages may not fit properly, resulting in rejected parts.”²

Burrs Are a Quality Issue.

“Burrs can have waves, or oscillations, that are either periodic or aperiodic with some machining parameter,” adds Dr. David Dornfeld, director of the Consortium on Deburring and Edge Finishing. Some of his research papers also describe the formation of small secondary burrs as the primary burrs peel from the workpiece and break like chips.

“Deburring is so fundamental to quality,” he observes. “Sometimes 30% of the cost of producing a part is spent getting rid of the burrs.” By simply being able to quantify burrs, one of his research teams was able to save one automaker about $50,000 per machine per year by tripling tool life.¹

Burrs Are a Safety Issue.

Burrs left on parts can cause lacerations to workers’ hands. Problems can also arise if a shop ships an improperly deburred part. For example, “blockage of orifices could result in a failure of an aircraft’s hydraulic systems—a potentially life-threatening event.”²

Instead of thinking of deburring as a secondary operation performed after machining, look for ways to integrate deburring into the production process.

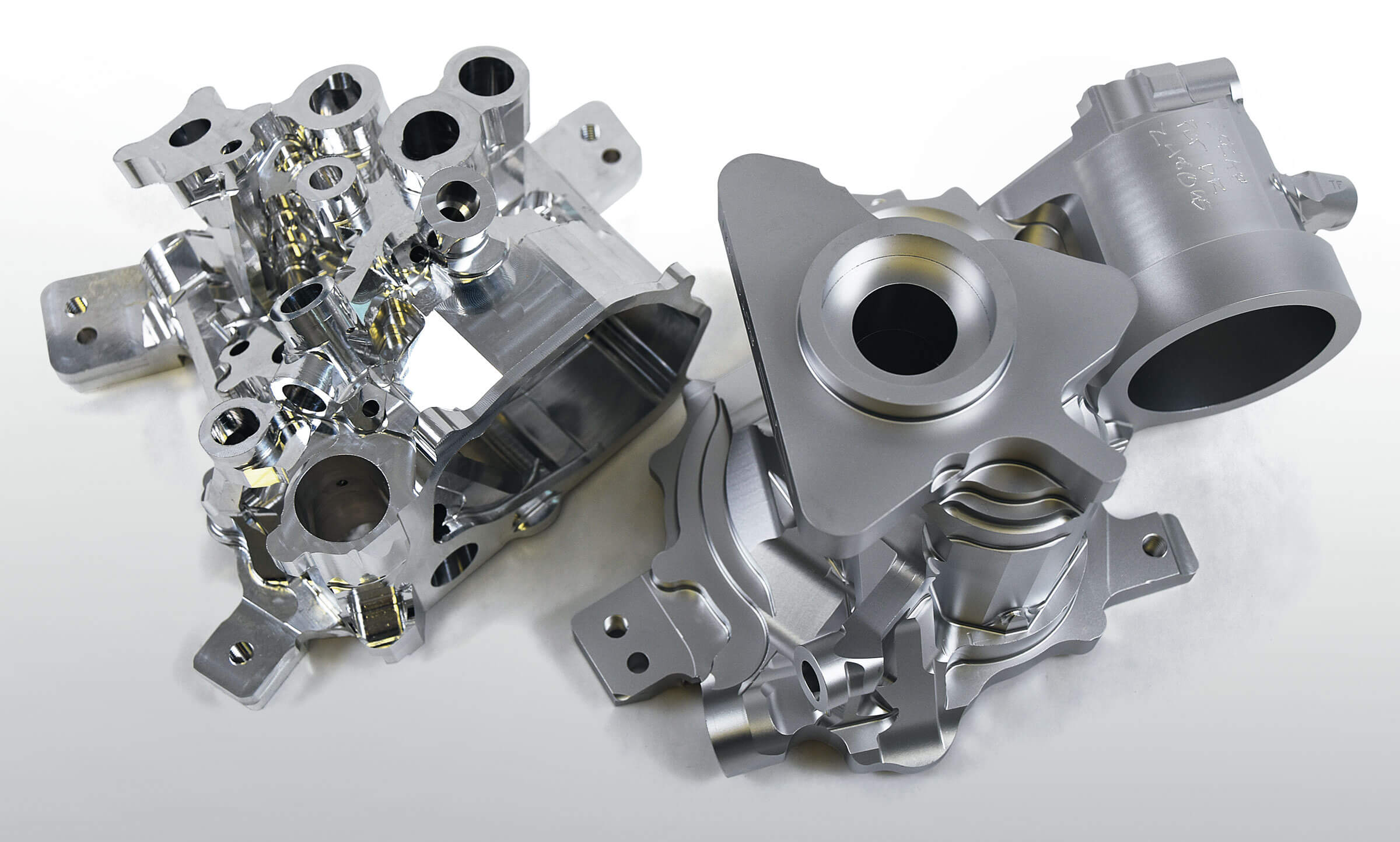

This part was deburred in a Wet Technologies system. Not only were burrs cleanly removed from the outer edges of the part, but also from internal passages and cross-drilled holes. The result is a smooth, uniform matte finish overall.

Deburring Should Not Be an Afterthought.

When the importance of deburring is minimized, serious quality and safety issues arise. Consider the removal of burrs during process design, and make it part of your organization’s training regimen. Give Wet Technologies a call to explore your options. Our engineers have decades of experience in this regard.

¹https://www.qualitymag.com/articles/83636-divining-edge-quality-by-reading-the-burrs

²https://www.ctemag.com/news/articles/deburring-essential-often-overlooked-process